Management

At the heart of every labelling machine is the control panel, which ensures a seamless flow of data, communication with PLCs and production systems. Its user interface is very clear and it is possible to monitor the detailed status of the machine. It helps to diagnose and troubleshoot potential problems and makes the job of material changeover easier.

Your intelligent control centre for a comprehensive overview

At the heart of every labelling machine is the control unit. It connects the electronic parts with the mechanical parts and ensures smooth interaction between control, IT systems and users.

Logopak's state-of-the-art system control units ensure trouble-free labelling processes by enabling constant monitoring and control of the equipment's status.

Full control

Many control units from other manufacturers leave many questions unanswered in the labelling process. Often the only information the operator receives from the control unit is whether the labelling system is currently in operation. In most cases, accessing the system or important basic information requires stopping the entire system and making a thorough visual inspection.

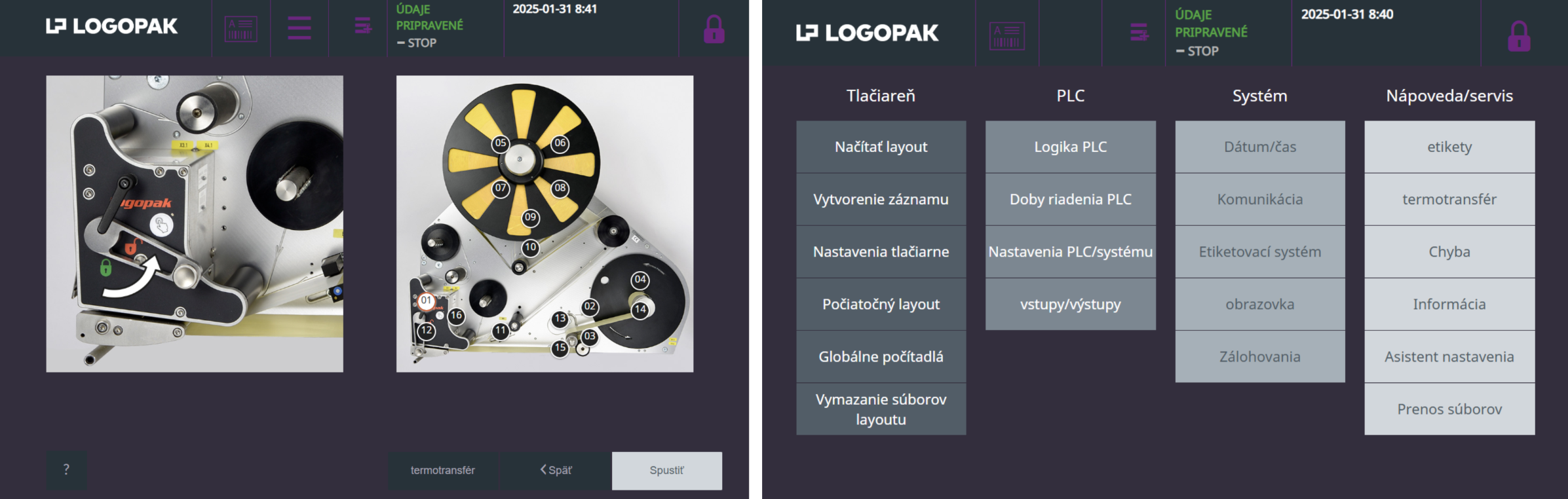

Logopak control panels with easy-to-read large touchscreen displays provide comprehensive and clear status information at any time during ongoing operations.

Unlike many conventional control units, Logopak units have a wide range of practical additional functions. For example, they are equipped with an automatic start-stop function, an integrated product visualisation system that shows the machine operator which label is currently being printed, or information on how much material is left until it is replaced. Also unique is the self-help system, which makes troubleshooting easier for the operator. A built-in OPC UA server allows interfacing with various SCADA systems for even greater visibility.

Simple user environment

Settings and process parameters often need to be changed quickly for a new product, but the displays of many conventional control units are simply too small or not very user-friendly. In addition, some manufacturers work with sub-controllers, making it difficult to know which display to use to adjust the relevant settings. Logopak controls provide access to all relevant process information on one central display. The system allows user profiles to be defined with different levels of access rights and can even be connected to remotely without having to be physically present at the control unit.

Ability to work autonomously

While other manufacturers' labelling devices are typically operated via external software, Logopak devices allow direct access to the internal product database, such as templates and logos, and enable test prints directly on the display. Their independence from other systems ensures that you can rely on production running smoothly even in the event of a temporary network outage.