Even a well-known online fashion store already has a warehouse marked with our technology

A bar-coded warehouse is now a prerequisite for optimal warehouse processes. With a suitable labelling system and the right labels, it is possible to achieve clarity, traceability and error-free operation of all warehouse processes and thus flexibility or speed of warehouse operations. Special labels made of highly resistant materials, suitable even for harsh conditions with special properties, are used for labelling warehouses.

This year, we have also provided warehouse labelling for one of the fastest growing online fashion retailers in Europe, which has decided to expand into Central and Eastern European markets. For this purpose, they chose a warehouse in the industrial park in Kostolné Kračany.

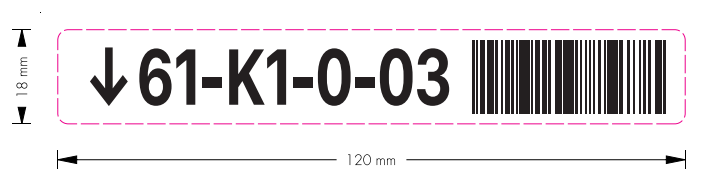

The 27,432 m2 warehouse uses a multi-level storage system Picktower I, II. It is a built-in 5-storey racking system including service conveyors and lifts. We marked 739,000 rack positions with high-strength plastic labels and as the customer lost the ability to mark the bottom rack with retrofitting, we designed a solution by marking from the first rack position using a reprinted arrow to direct the warehouseman to the correct position.

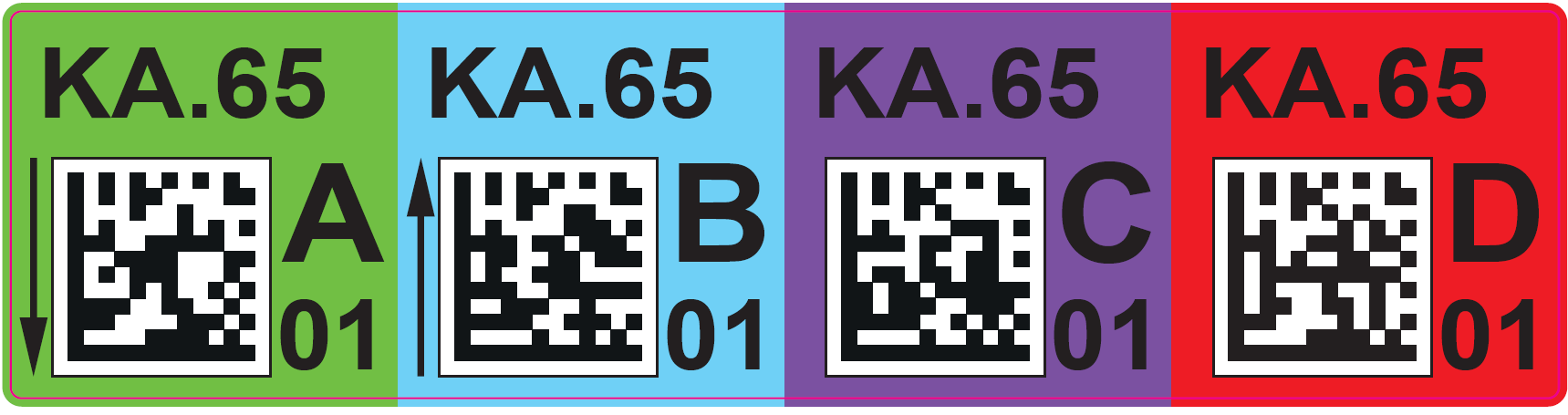

9,000 large format labels were used to mark the aisles, with distinctive colour coding to ensure easy orientation of warehouse staff within the warehouse. We placed labels at each shelf start/end and wherever a warehouse worker is in the space, they can easily find their way by following the labels.

Our labels were again used to mark the warehouses of Dr. Max and dm drogerie markt after the move to the new premises.

Thanks to the introduction of the WMS K. Motion Warehouse Edge has significantly increased the efficiency of the warehouse, so they have again decided to mark their new warehouse areas with our labels. A total of 15,970 warehouse positions were marked with plastic labels, of which 1,164 were marked with special "Multilevel" labels. The advantages of these labels are in particular the ability to scan all positions from one central label, to position positions at eye level and the ability to colour-code the individual floors for even better orientation of the warehouse staff. They are made from special plastic materials that are resistant to damage, chemicals and UV rays.

After moving to a new 30,000 m2 warehouse, dm drogerie markt also used our labels again to mark 26,169 pallet positions. Its warehouse consists of pallet positions ranging from 3 to 11 levels, where 4,730 "Multilevel" labels have been applied, which, due to their positioning on the first beam at the warehouseman's eye level, allow any position to be easily and quickly scanned.